MARTEC Aviation provides specialized NDT services throughout the United States, Latin America, the Caribbean, Asia, and the Middle East. We are equipped to conduct in-house and on-site inspections, and can mobilize anywhere in the world within a moments notice once a project has been secured. Our guarantee is to provide you with the most expedient turnaround time possible to allow you to meet your aircraft maintenance goals.

MARTEC Aviation can also assist you with training of your in-house NDT personnel in any or all of the NDT methods we offer. Our team is made up of well trained and experienced ASNT and NAS-410 Certified NDT Level 3 and Level 2 professionals. We have extensive experience working with private and commercial air carriers, DOD and DOT customers in addition to parts manufactures, parts brokers, machine shops, and other FAA/EASA certified repair stations.

NDT Level 3 Services

Authorized Independent Outside Agency

Our team of consultants can assist you with a variety of NDT Level 3 services such as, developing written practices, procedures, and work instruction; project management and manpower augmentation during heavy workload periods.

Training

We can formally train your NDT prospects to Level 1, 2, or 3 in one or several NDT Methods, including Radiation Safety depending on your needs.

Courses can be taught per SNT-TC-1A, NAS-410, CP-189, or can be designed to meet your individual needs.

We provide the theoretical knowledge and qualifications needed to succeed in the NDT industry.

Auditing

Our experienced auditors can provide auditing and surveillance services of your in-house NDT Program and/or authorized vendors.

We can provide comprehensive quality system audits or auditing of specific areas such as NDT and Radiation Safety.

Radiation Safety

The biological effects of radiation require that safe handling and operation of ionizing radiation machines and isotope sources meet strict State and Federal regulations.

We have Radiation Safety Officers that can assist you in developing a Radiation Safety Manual, and safety training for your radiation workers to ensure that your company maintains a safe work environment for your employees and members of the public.

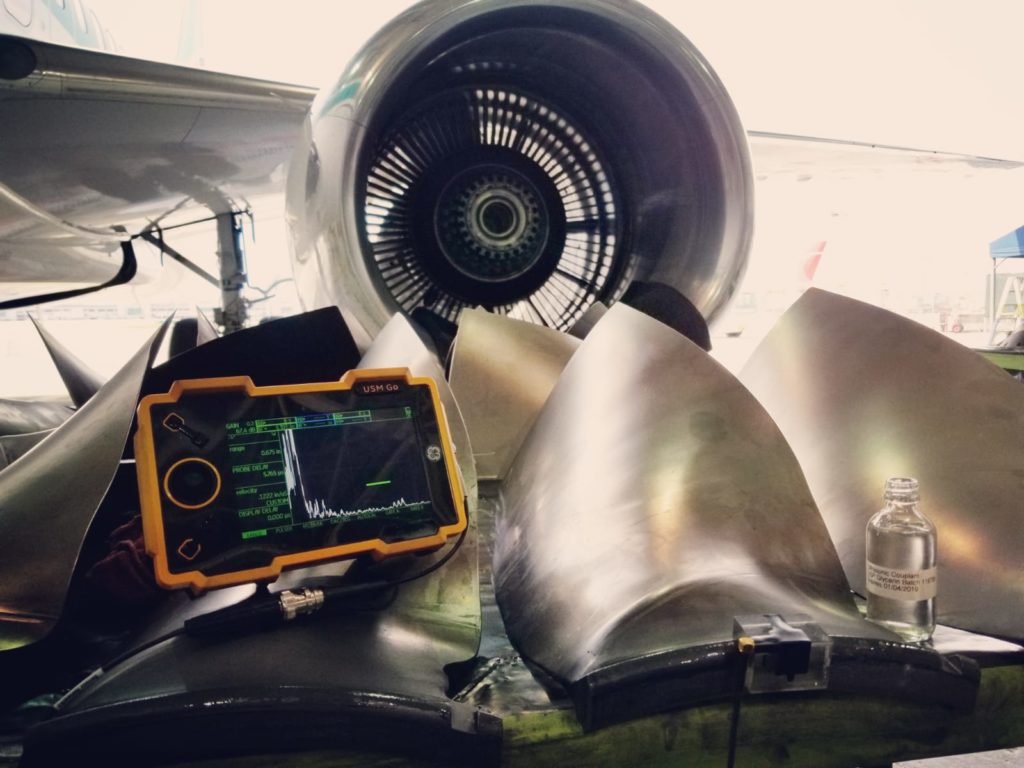

NDT Inspection Methods

The following provides a brief description of the nondestructive testing method offered at MARTEC Aviation. Nondestructive testing is the means of evaluating an objects structural health condition without impairing the objects usefulness. Nondestructive testing is used widely in the aviation industry to ensure that aircraft, parts, and components are safe and airworthy.

Visual testing is the observation of a test object, either directly with the eye or indirectly using optical instruments to evaluate the presence of surface discontinuities, and the objects conformance to specification. Visual testing is the first NDT method applied when examining any object.

The process of coating the test specimen with a fluorescent dye. The dye penetrant is allowed to dwell on the part for a specific amount of time, the excess penetrant solution is removed from the surface, and a developer is applied to draw out the penetrant left behind in surface defects.

This method is accomplished by inducing a magnetic field in a ferromagnetic material and then applying either dry or wet iron particles to the surface of the test piece. When a surface or subsurface discontinuity interrupts the magnetic field the iron particles will form an outline of the leakage field revealing its location, size and shape.

Eddy Currents are generated in a conductive material by a changing magnetic field. Indications are noted when the flow of eddy currents is interrupted by a surface defect. These electrical currents are also affected by the electrical and magnetic permeability of a material.

Ultrasonic testing involves using sound energy to evaluate an object for internal flaws, thickness measurements, or bond characterization.

Radiography utilizes x-ray or gamma radiation to produce an image on a piece of film (or detector) of the internal structure of a part. The test requires access to the top and back surfaces of the test piece. However, little to no surface preparation is required.